Cold Spray Digital Twin Framework

High-Fidelity Simulation for Synthetic Data Generation and Intelligent Manufacturing

Project Vision

Cold spray additive manufacturing produces complex, non-Gaussian deposition patterns that are difficult to predict and control. This project develops a comprehensive digital twin framework that generates high-fidelity synthetic data for training surrogate models, ultimately enabling intelligent control of cold spray robotic systems.

The framework leverages NVIDIA's parallel computing tools and robotics platforms to create accurate simulations of the cold spray process, capturing the non-ideal deposition characteristics essential for training physics-informed neural networks. This synthetic data pipeline eliminates costly physical experimentation while providing the diverse training data necessary for developing robust control policies.

Technical Architecture

The system integrates three core components to create a complete digital twin:

- Custom Physics Simulation (Warp): GPU-accelerated deposition modeling using NVIDIA Warp's parallel computing framework to achieve real-time performance

- Robotic Framework (Isaac Sim): Modular robot control system supporting multiple manipulators and control strategies

- Intelligent Segmentation (SDFs): Real-time defect detection and repair planning using GPU-accelerated signed distance fields

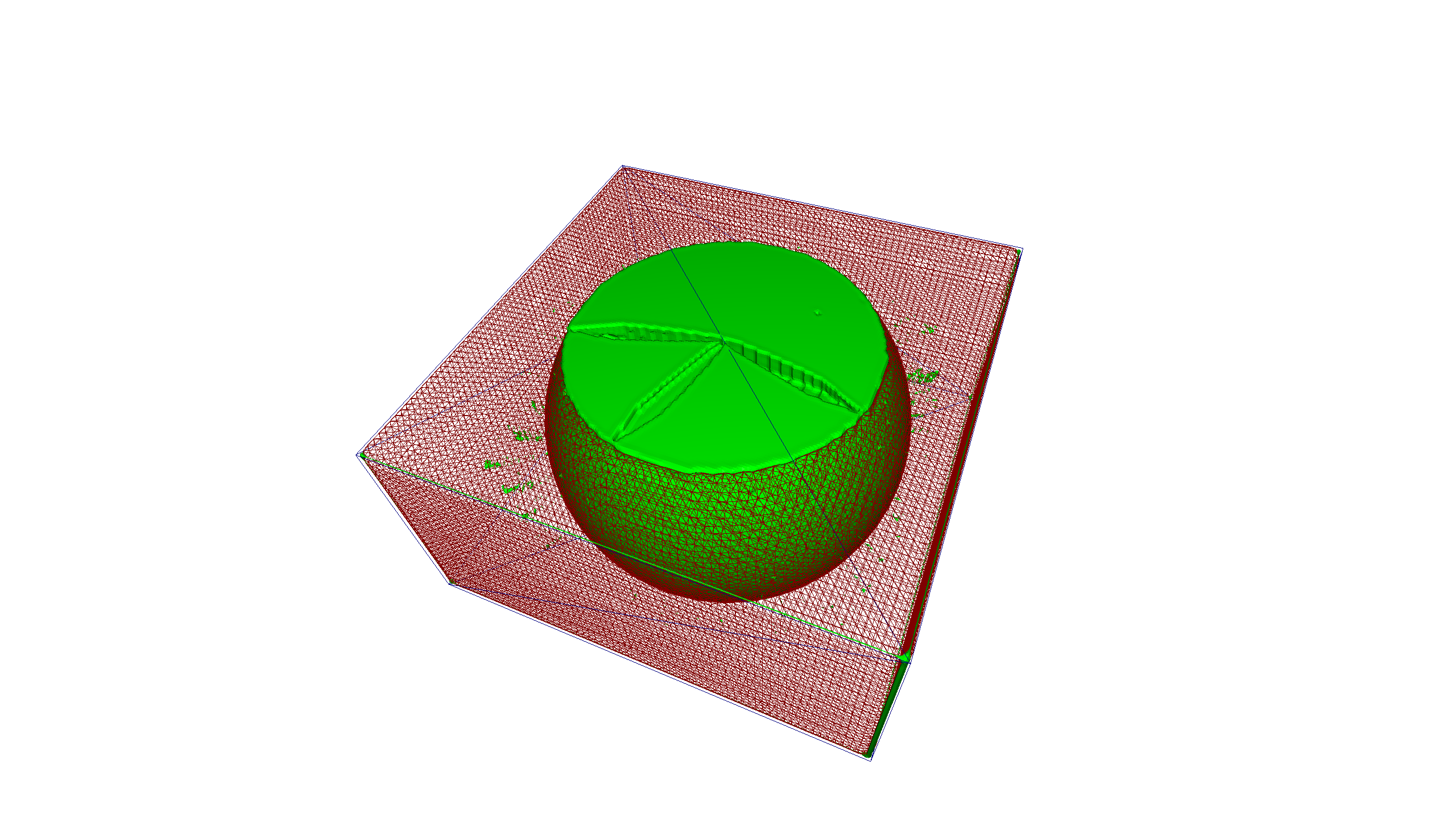

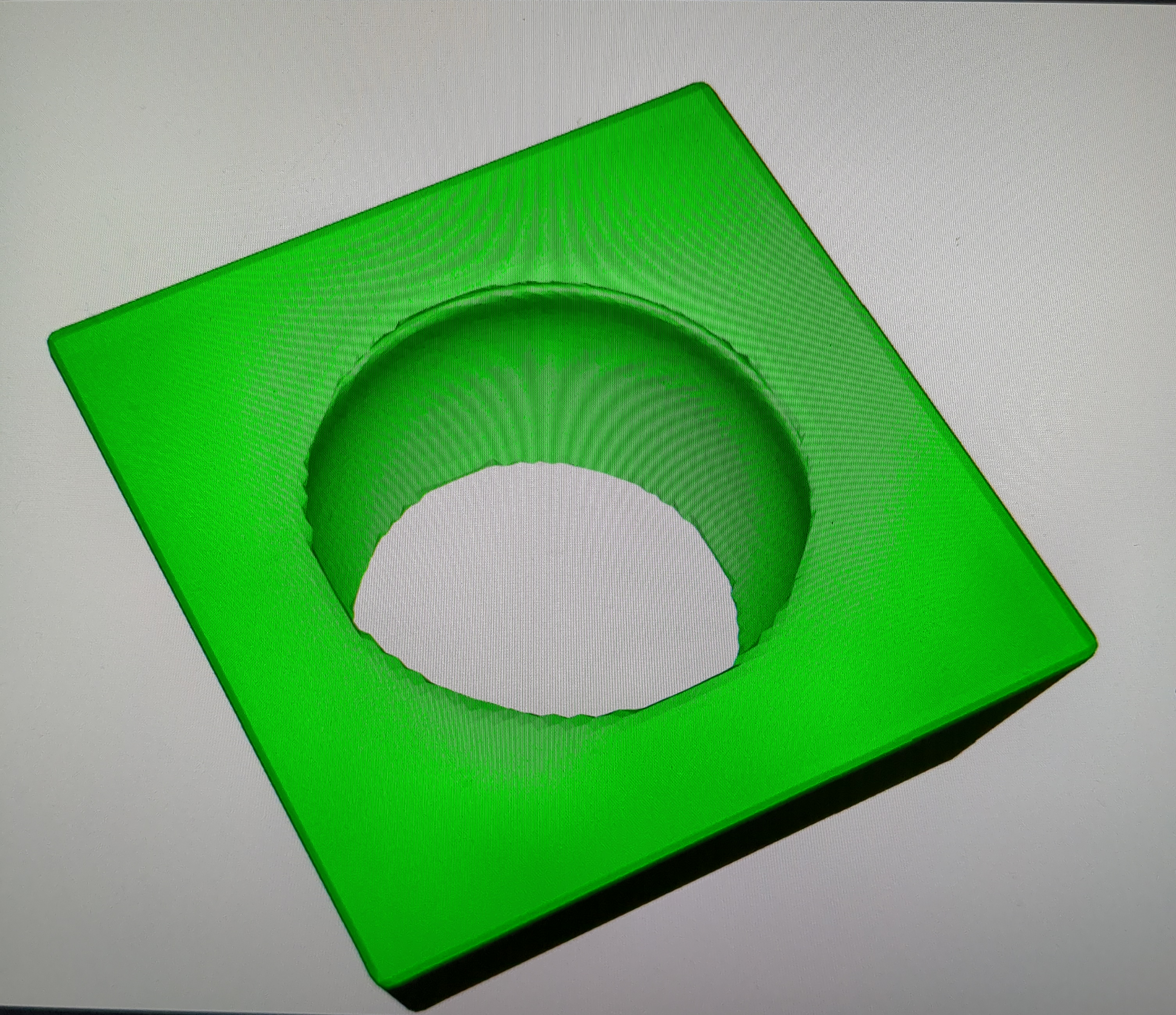

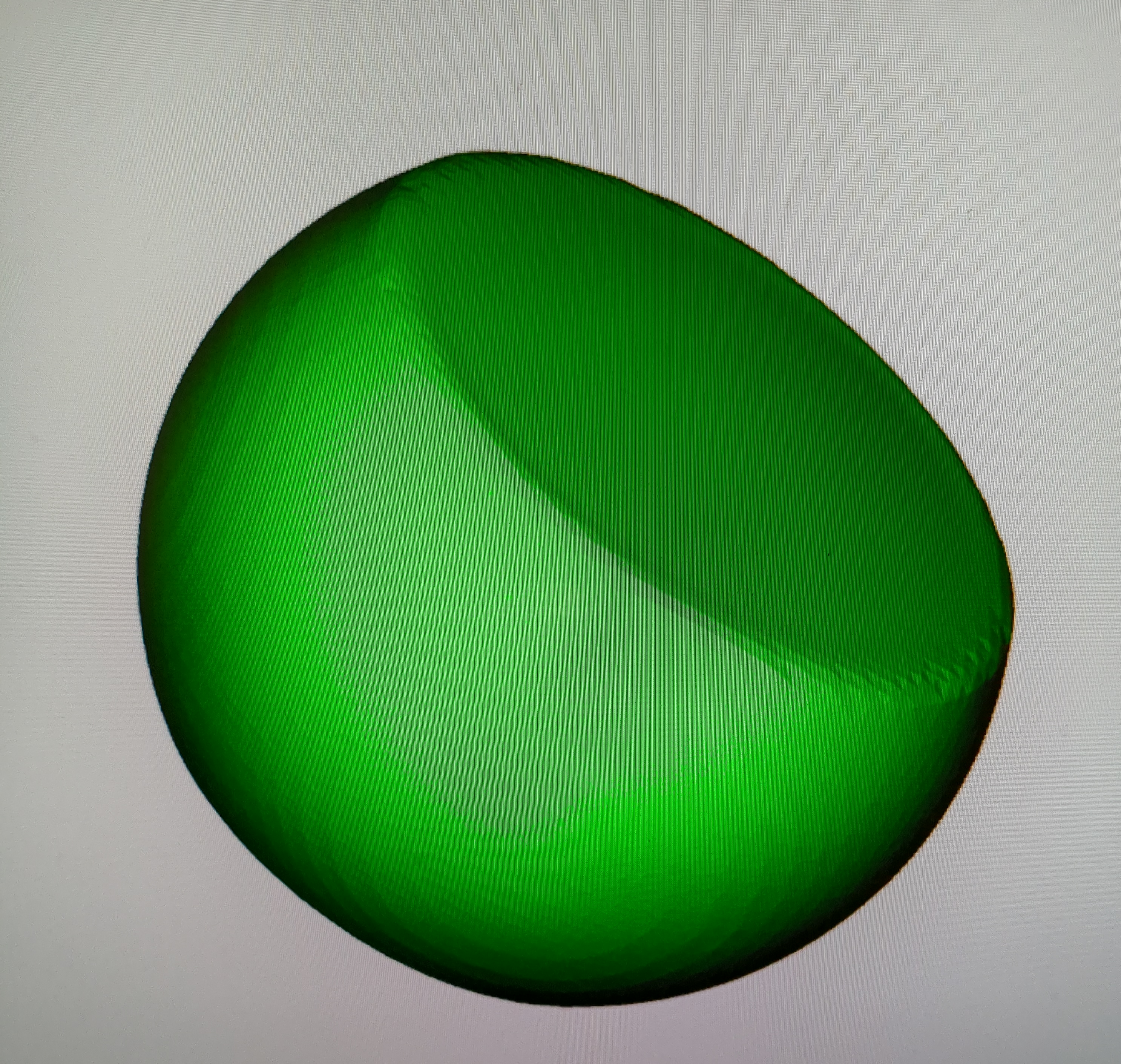

Core Innovation: GPU-Accelerated Cold Spray Simulation

Real-Time Physics Using Warp

Developed custom CUDA kernels using NVIDIA Warp's parallel computing framework to simulate cold spray deposition at unprecedented speeds:

- Non-Gaussian Deposition: Accurate modeling of realistic spray patterns that deviate from ideal distributions

- GPU-Accelerated Raycasting: High-throughput ray-mesh intersection for deposition simulation

- Dynamic Mesh Deformation: Real-time vertex manipulation to simulate material buildup

- Material-Specific Models: Customizable deposition parameters for different powder materials

- Differentiable Simulation: Full autodiff support for gradient-based optimization

Synthetic Data Generation Pipeline

The simulation generates diverse training scenarios for surrogate model development:

- Automated Scenario Generation: Thousands of spray configurations with varying parameters

- Ground Truth Labels: Accurate deposition thickness and quality metrics

- Domain Randomization: Systematic variation for robust model training

- PhysicsNeMo Ready: Output format optimized for physics-informed neural networks

Isaac Sim: Modular Robotics Framework

Robot-Agnostic Architecture

Built a comprehensive framework supporting multiple industrial robots through a unified interface:

- Modular Design: Plug-and-play support for UR, KUKA, ABB, and xArm robots

- Controller Flexibility: RMPflow for reactive motion, custom IK solvers for path following

- Task Modularity: Configurable for various manufacturing operations

- USD Integration: Seamless CAD import and collaborative workflows via Omniverse

FabMachine Library

Custom library implementing diverse manufacturing processes:

- Additive Processes: Cold spray, 3D printing, and deposition operations

- Subtractive Processes: Machining and material removal simulation

- Hybrid Operations: Combined additive-subtractive workflows

Enabling Technology: SDF-Based Intelligence

Signed Distance Fields provide the computational backbone for real-time decision making:

GPU-Accelerated Segmentation

- Microsecond Performance: Defect detection in microseconds using CUDA kernels

- Boolean Operations: Efficient computation of repair regions (target - current)

- 3D Array Representation: Direct GPU manipulation for maximum performance

- Quality Metrics: Real-time chamfer distance computation for accuracy assessment

Dual-Purpose Application

- Reward Computation: SDF differences drive reinforcement learning rewards

- Repair Planning: Automatic identification of regions requiring deposition

- Process Monitoring: Continuous evaluation of coating uniformity

Digital Twin Integration

The framework seamlessly combines simulation components for complete digital twin functionality:

System Architecture

- Bi-directional Communication: Real-time data exchange between physics and robotics layers

- Hardware Integration: Direct control of xArm6/7 robots via ROS2

- Parallel Processing: Asynchronous execution of physics and robot control

- Cloud Scalability: Distributed training support for large-scale data generation

Performance Metrics

- Simulation Speed: 60+ FPS with full physics on RTX 4090

- Data Generation: 10,000+ unique scenarios per hour

- Segmentation Speed: Microsecond defect detection

- Accuracy: Deposition predictions within 5% of physical measurements

Future Applications: Learning-Based Control

Once surrogate models are trained on synthetic data, the framework enables:

Reinforcement Learning in Isaac Lab

- Smooth Spray Control: RL policies for uniform deposition with constant flow rate

- Adaptive Repair: Intelligent strategies for defect remediation

- Multi-Operation Planning: Coordinated additive-subtractive workflows

- Sim-to-Real Transfer: Domain randomization for robust deployment

Industrial Applications

- Aerospace: Automated turbine blade repair

- Automotive: EV component coating

- Remanufacturing: Intelligent part restoration

Technical Stack & Contributions

Parallel Computing

- NVIDIA Warp (CUDA wrapper)

- Custom GPU kernels

- Differentiable programming

- Real-time raycasting

Robotics & Simulation

- NVIDIA Isaac Sim

- Isaac Lab (future RL)

- RMPflow planning

- ROS2 integration

Machine Learning

- Synthetic data generation

- PhysicsNeMo preparation

- SDF-based rewards

- Hyperparameter optimization

Key Contributions

- First real-time cold spray simulator with accurate non-Gaussian deposition using GPU acceleration

- Comprehensive synthetic data pipeline for training physics-informed neural networks

- Microsecond defect segmentation using GPU-accelerated SDF operations

- Modular robotics framework supporting multiple robots and control strategies

- Complete digital twin architecture bridging simulation and physical systems

This framework establishes the foundation for intelligent, data-driven manufacturing systems that can adapt and optimize in real-time, significantly advancing the state of cold spray technology.

For more information: Contact me because the repository for this project is a part of an active research effort